The Indispensable Role of Diagnostic Tools

Diagnostic tools have become the backbone of modern truck repair, revolutionizing the way technicians identify and troubleshoot issues. Gone are the days of relying solely on hunches and guesswork, as these tools provide mechanics with accurate insights into the intricate workings of a truck’s various systems. With their ability to analyze complex data and pinpoint problems swiftly, diagnostic tools have transformed the efficiency and effectiveness of repairs, reducing downtime and ensuring vehicles are back on the road promptly.

These tools have enabled mechanics to delve beneath a truck’s surface, accessing real-time data from sensors, control modules, and other vital components. By simply plugging into a vehicle’s On-Board Diagnostics (OBD) port or connecting wirelessly through advanced interfaces, technicians can access an ocean of information that would otherwise remain hidden.

From engine performance analysis to tracking emission levels or detecting faults within electrical systems, these diagnostic tools serve as trusted companions in diagnosing issues accurately. In today’s rapidly evolving world of truck repair, possessing comprehensive knowledge about these advanced tools has become indispensable for any professional seeking to stay ahead in the field.

History of Diagnostic Tools in Truck Repair

The foundations for modern diagnostic tools can be traced back several decades when rudimentary scanning devices started surfacing alongside increased electronic integration in trucks. These early tools provided limited capabilities compared to today’s sophisticated counterparts but marked a significant shift toward data-driven diagnostics.

Over time, advancements led to more comprehensive interfaces capable of reading manufacturer-specific trouble codes (DTCs) and providing valuable insights into a vehicle’s health. In recent years, substantial strides have been made regarding both hardware and software capabilities.

With rapid advancements in computer technology paired with improved connectivity options such as Bluetooth or Wi-Fi integration, diagnostic tools have become more versatile and user-friendly. Alongside this, the development of advanced algorithms and diagnostic software has expanded the range of systems that these tools can analyze.

From engine management systems to transmission controls, anti-lock braking systems (ABS), and beyond, modern diagnostic tools now offer a holistic approach to truck diagnostics. As trucks continue to evolve with newer electronics, intricate sensors, and CAN bus communication networks, the need for advanced diagnostic tools becomes increasingly evident.

The history of these tools is intertwined with the continual progression of truck repair itself – a journey defined by improved accuracy, enhanced efficiency, and an ever-expanding scope of capabilities. In this article, we will explore some of the most commonly used diagnostic tools while venturing into lesser-known yet highly valuable resources that empower technicians in their pursuit of resolving truck-related mysteries.

High-Level Overview of Commonly Used Diagnostic Tools

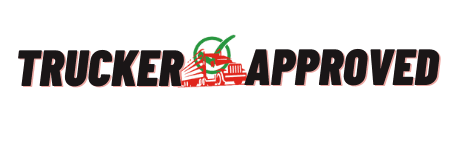

On-Board Diagnostics (OBD) Scanners

In the realm of truck repair, OBD scanners are the unsung heroes. These compact handheld devices are an essential tool for any technician looking to discover potential issues lurking within a truck’s complex internal systems.

OBD scanners plug into the vehicle’s On-Board Diagnostic port, usually located under the dashboard or steering column. Once connected, they communicate with the truck’s onboard computer and retrieve vital information regarding engine performance, emissions, and other diagnostic trouble codes.

The functionalities of OBD scanners go beyond simple code reading. They can provide real-time sensor data, allowing technicians to monitor key parameters like engine RPM, coolant temperature, fuel trim values, and much more.

Some advanced OBD scanners even offer freeze-frame data that captures sensor readings at the time a fault occurs. This feature enables technicians to analyze crucial information to pinpoint specific issues accurately.

Computerized Engine Analyzers

Computerized engine analyzers take diagnostic capabilities to another level by providing in-depth analysis of a vehicle’s engine performance. These powerful tools allow technicians to access live data streams from various sensors within the engine system while simultaneously running comprehensive tests on critical components.

Engine analyzers can assist in diagnosing complex problems such as misfires, fuel injection system malfunctions, ignition timing issues, and even valve train abnormalities. By analyzing data from different sensors simultaneously, these tools can help identify patterns or inconsistencies that may point toward specific mechanical or electrical faults.

Moreover, modern engine analyzers come equipped with extensive databases containing manufacturer-specific diagnostic information for various truck models. This invaluable resource allows technicians to access troubleshooting guides for specific symptoms or fault codes related to particular trucks—saving precious time during diagnosis and ensuring accurate repairs.

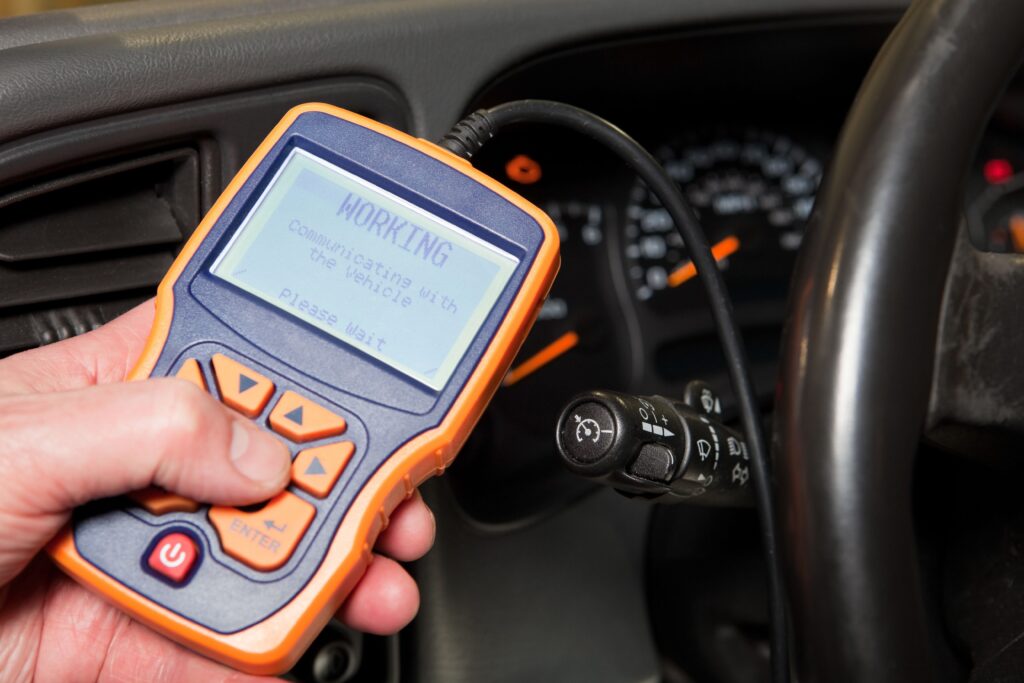

Multimeters for Electrical System

When it comes to troubleshooting truck electrical systems, multimeters are the go-to instruments for technicians. Multimeters are versatile devices capable of measuring voltage, current, and resistance. With their help, technicians can evaluate the integrity of electrical circuits, identify open or shorted wires, and measure component performance.

By using a multimeter in conjunction with wiring diagrams and schematics specific to a truck model, technicians can perform a range of tests to assess the health of various electrical components. They can measure voltage drops across connections, test continuity between two points in a circuit, or even diagnose faulty sensors.

Furthermore, modern multimeters often come equipped with advanced features like diode testing and frequency measurement capabilities. These additional functionalities make them indispensable tools not just for diagnosing truck electrical systems but also for general troubleshooting tasks in any automotive setting.

OBD scanners provide vital information about a truck’s internal systems by retrieving diagnostic trouble codes (DTCs) and real-time sensor data. Computerized engine analyzers take diagnostics further by analyzing comprehensive data streams from various engine sensors to identify complex issues accurately.

Multimeters serve as versatile tools for diagnosing electrical system problems by measuring voltage drops, continuity checks, and component performance evaluations. These commonly used diagnostic tools form the foundation of any competent technician’s arsenal when it comes to tackling truck repairs effectively.

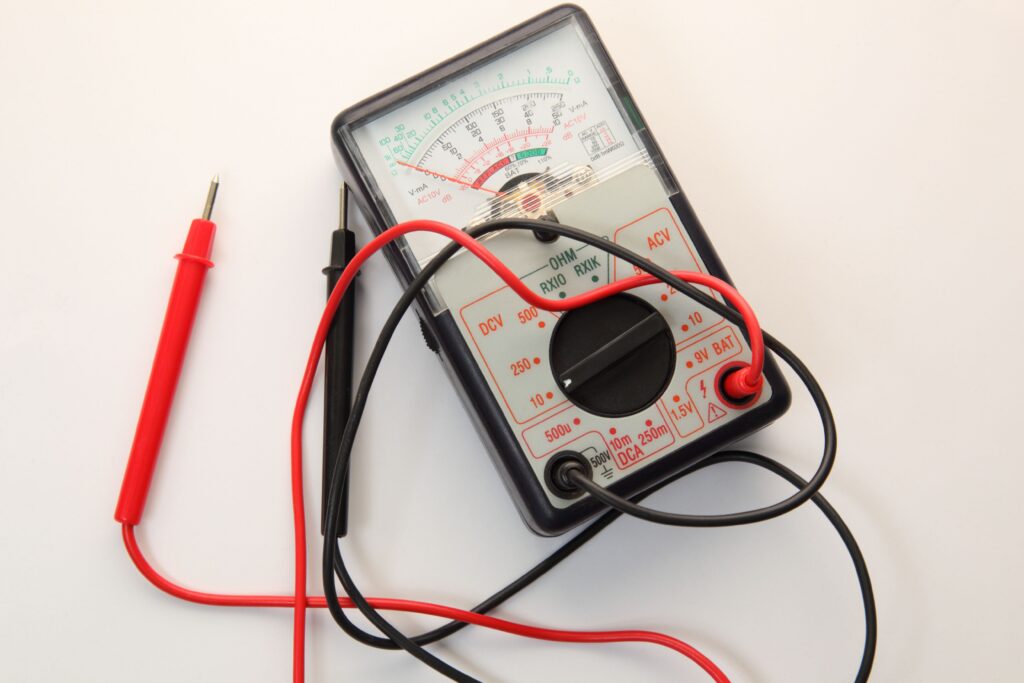

Oscilloscopes

Oscilloscopes, with their ability to capture and display electrical waveforms, are indispensable tools for diagnosing complex electrical issues in trucks. They allow technicians to visualize the behavior of electrical signals in real-time, providing valuable insights into the health and functionality of various components. But what makes oscilloscopes truly powerful are their features and benefits that make troubleshooting a breeze.

One of the key features of oscilloscopes is their ability to measure voltage, frequency, and time intervals accurately. With this information at hand, technicians can identify irregularities or abnormalities in electrical signals.

Additionally, modern oscilloscopes come equipped with advanced triggering capabilities that enable users to capture specific sections or events within a waveform for detailed analysis. This allows for precise pinpointing of intermittent faults like erratic sensor readings or faulty connections.

The practical applications of oscilloscopes in truck repair span across various systems. For instance, when troubleshooting ignition systems, technicians can use an oscilloscope to analyze the firing patterns of spark plugs and identify any misfires or irregularities.

Similarly, when dealing with fuel injection systems, an oscilloscope can reveal injector performance issues by displaying injector pulse width and shape. By leveraging these features and applications, skilled technicians armed with an oscilloscope can swiftly diagnose complex electrical problems that would otherwise be elusive.

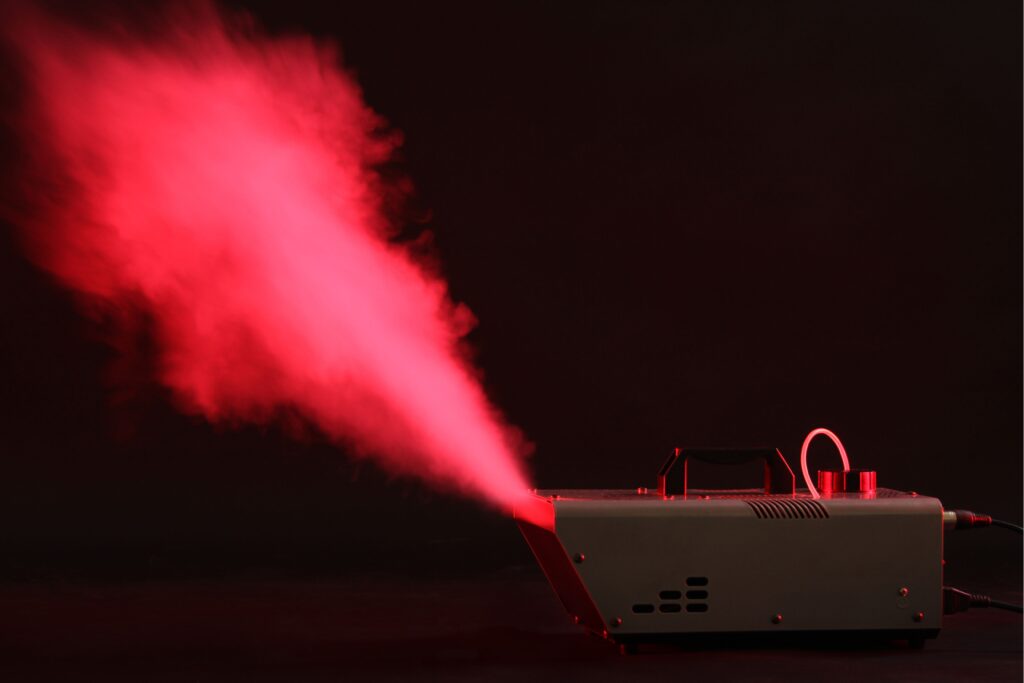

Smoke Machines

In the world of truck repair diagnostics, finding air/vacuum leaks has always been a challenge due to their elusive nature. However, smoke machines have emerged as game-changers in this realm by providing an efficient way to detect these hidden leaks effortlessly. So how do smoke machines work?

Essentially, they create artificial smoke using non-toxic substances such as mineral oil or glycerin-based solutions. This smoke is then introduced into the truck’s intake system or any other suspected area.

As the smoke disperses, it reveals the presence of leaks by escaping through even the tiniest gaps or cracks. Technicians can visually observe this smoke and trace its path to pinpoint the exact source of leakage.

The advantages of using smoke machines over traditional leak detection methods are significant. Firstly, they allow for quick and accurate identification of leaks without disassembling components or conducting time-consuming pressure tests.

Secondly, smoke machines can detect leaks in complex systems that would be challenging to access otherwise. For example, locating a vacuum leak behind an engine block becomes much simpler when smoke is used as a visible indicator.

These machines are versatile enough to be used for various applications beyond air/vacuum leak detection, such as evap system testing or detecting exhaust leaks. With their ease of use and effectiveness, it’s no wonder that smoke machines have gained popularity among technicians in truck repair diagnostics.

Thermal Imaging Cameras

When it comes to diagnosing cooling system problems in trucks, thermal imaging cameras offer a unique perspective that goes beyond what meets the eye. By harnessing infrared technology, these cameras can detect temperature variations and generate visual representations called thermograms. The principles behind thermal imaging technology lie in capturing infrared radiation emitted by objects based on their temperatures.

Truck technicians can utilize these cameras to identify hotspots or cold spots within cooling systems that may indicate issues like clogged radiators, malfunctioning water pumps, or faulty thermostats. By pinpointing specific areas with abnormal temperatures on the thermograms provided by thermal imaging cameras, technicians can efficiently diagnose cooling system problems without physically inspecting every component.

The advantages of using thermal imaging cameras extend beyond cooling systems as well. They can be employed for diagnosing electrical malfunctions caused by overheating components like alternators or relays.

Additionally, these cameras can be used to detect poor insulation or energy loss on exhaust systems, identifying areas where heat is escaping or additional insulation is required. With their ability to visualize temperature variations, thermal imaging cameras empower technicians to swiftly diagnose issues that may not be visible to the naked eye, leading to efficient and precise repairs.

Enhancing Diagnostic Capabilities

Behind the scenes, advanced diagnostic tools rely on a technology known as Controller Area Network (CAN) bus systems to enhance their capabilities and provide accurate diagnoses for truck repairs.

The CAN bus acts as a communication network between various electronic control units (ECUs) in modern trucks, allowing them to exchange data seamlessly. This integration enhances the diagnostic process by providing real-time access to vital information from multiple systems, enabling technicians to pinpoint issues more efficiently.

One crucial advantage of using CAN bus systems is their ability to retrieve trouble codes from different ECUs simultaneously. In traditional diagnostic methods, technicians would have had to scan each ECU separately, which was both time-consuming and inefficient.

With CAN bus systems, however, the scanning process becomes streamlined as all relevant data can be accessed through a single interface. Moreover, this comprehensive approach allows for better analysis and interpretation of interrelated faults across various systems within the truck.

Furthermore, CAN bus systems enable live data monitoring during diagnostics. Technicians can observe sensor readings and parameter values in real-time through special software integrated with advanced diagnostic tools.

This invaluable feature facilitates the identification of intermittent issues that may not be readily apparent during static inspections or road tests alone. By closely analyzing live data from multiple ECUs simultaneously, technicians gain greater insights into complex problems that may have otherwise eluded detection.

Hidden Features and Advanced Settings on Popular Diagnostic Tools

While many technicians are familiar with basic functionalities offered by popular diagnostic tools, these powerful devices often hide hidden features and advanced settings that can significantly enhance their effectiveness in truck repair diagnostics.

For instance, some high-end scanners offer deep system resets that go beyond clearing fault codes; they enable the reinitialization of specific control modules or even perform adaptive learning processes for improved performance after repairs. These advanced features can tackle complex issues like erratic fuel trims, idle fluctuations, or driveability problems that standard diagnostic procedures may overlook.

Another concealed gem in many diagnostic tools is the capability to access manufacturer-specific service information and technical bulletins directly. By leveraging these hidden features, technicians can stay up-to-date with the latest repair procedures, software updates, and troubleshooting tips directly from the truck manufacturer.

This invaluable resource ensures that technicians have all the necessary information at their fingertips to tackle even the most perplexing problems. Moreover, some advanced diagnostic tools offer customizable options for specialized tasks.

Technicians can fine-tune parameters such as data refresh rates, and voltage thresholds for sensor testing, and even customize graphical user interfaces according to their preferences. These hidden settings allow technicians to tailor their diagnostic tools to match their specific needs and work efficiently in their preferred way.

Exploring Emerging Technologies That May Revolutionize Truck Diagnostics

Truck diagnostics is a field where constant innovation drives progress. As technology evolves at a rapid pace, several emerging technologies show immense promise for revolutionizing truck diagnostics further.

One exciting development on the horizon is artificial intelligence (AI) integration within diagnostic tools. AI algorithms can learn from vast amounts of data collected over time and provide more accurate fault predictions based on patterns observed across different trucks and systems.

This predictive capability would enable proactive maintenance planning, preventing potential failures before they occur. Additionally, advancements in wireless connectivity may soon enable remote diagnostics via cloud-based platforms.

Imagine a scenario where technicians could access real-time data from trucks located anywhere in the world using secure internet connections. This would facilitate efficient troubleshooting regardless of geographical limitations and potentially reduce downtime significantly.

Furthermore, augmented reality (AR) technology holds great potential in assisting technicians during truck repairs by overlaying digital information onto physical components or systems through smart glasses or mobile devices. AR-based guidance could present step-by-step repair instructions, highlight problematic areas, and even provide real-time technical support from experts located remotely.

The role of CAN bus systems in enhancing diagnostic capabilities, the discovery of hidden features in popular diagnostic tools, and the exploration of emerging technologies are pivotal aspects shaping the future of truck diagnostics. By leveraging these advancements and staying at the forefront of technological progress, technicians can continue to provide efficient and accurate repairs for modern trucks.

Advanced Diagnostic Tools

Ongoing Advancements

As technology continues to evolve at a rapid pace, so do advanced diagnostic tools in the truck repair industry. Manufacturers are constantly pushing the boundaries of innovation, developing cutting-edge tools that provide more accurate and efficient diagnostic capabilities.

These advancements have a profound impact on how technicians diagnose and solve complex issues in trucks. One major trend in advanced diagnostics is the integration of artificial intelligence (AI) algorithms into diagnostic software.

AI-powered tools can analyze vast amounts of data from a truck’s systems, pinpointing potential problems with incredible accuracy. This not only saves time but also improves the overall precision of diagnostics.

Additionally, remote diagnostics are becoming more prevalent, allowing technicians to connect to trucks remotely and perform diagnostic tests without physically being present. This enables quicker response times and reduces downtime for truck operators.

The Importance of Continuous Training

As advanced diagnostic tools become more sophisticated, technicians must receive proper training to effectively utilize these tools. Continuous training ensures that technicians stay up-to-date with the latest advancements, enabling them to make full use of these powerful diagnostic instruments. Training programs should cover not only how to operate different diagnostic tools but also provide comprehensive knowledge about vehicle systems, electrical circuits, and computerized engine management systems.

Technicians should also be trained in interpreting complex data generated by advanced diagnostic tools accurately. By investing in continuous training programs for their technicians, repair shops can ensure that they stay competitive in the industry while providing reliable service to their customers.

Skilled technicians who are well-versed in using advanced diagnostic tools will be able to diagnose issues quickly and accurately, reducing repair time and costs while improving customer satisfaction. The future of advanced diagnostic tools in truck repair looks promising due to ongoing technological advancements.

These innovations have a profound impact on the industry, enhancing diagnostic accuracy and efficiency. However, technicians need to embrace continuous training to master these tools effectively.

By staying up-to-date with the latest advancements and honing their skills, technicians can ensure that they are well-equipped to tackle complex truck repair issues. With the combination of advanced diagnostic tools and skilled technicians, the future of truck repair holds great potential for efficient and effective troubleshooting, resulting in fewer breakdowns and improved overall performance for trucks on our roads.