The fuel systems in trucks plays a crucial role in ensuring smooth operation and optimal performance. It is a complex network of components that work together to deliver fuel from the tank to the engine, providing the necessary energy for combustion. A well-functioning fuel system is essential for maintaining engine efficiency, power output, and overall reliability.

The fuel system in trucks refers to the interconnected components responsible for storing, delivering, and metering fuel to the engine. It starts with a fuel tank, where gasoline or diesel is stored until it is needed.

From there, the fuel pump draws the fuel and sends it through various channels to reach the engine cylinders. The process involves filtration through fuel filters and injection by fuel injectors into each cylinder for combustion.

Importance of a Well-Functioning Fuel System

A well-maintained and properly functioning fuel system in trucks is vital for several reasons. Firstly, it ensures efficient delivery of clean, uncontaminated fuel to the engine. This directly impacts combustion efficiency, preventing issues such as misfires or incomplete combustion that can lead to decreased power output and increased emissions.

Secondly, a well-functioning fuel system promotes better overall engine performance and longevity. Properly metered and distributed amounts of fuel allow for consistent power delivery while minimizing wear on critical engine components such as pistons and valves.

An optimized fuel system contributes to improved mileage or efficiency by providing an appropriate air-fuel mixture ratio at all times. This not only reduces operational costs but also aligns with environmental concerns by minimizing harmful emissions.

Overview of Common Issues and Solutions

Despite their importance, truck’s fuel systems can encounter various issues that affect their performance. These problems can range from contaminated fuels resulting in clogged filters or injectors to pump failures due to wear or electrical faults.

Having a broad understanding of these common issues and their corresponding solutions can help truck owners and operators address potential problems proactively. In the following sections, we will delve into the specific components of the fuel system, discussing their functions, common issues that arise, and effective solutions.

We will explore topics such as fuel contamination, pump failures, clogged filters, and injector problems. By gaining insights into these challenges and their resolutions, truck owners can take appropriate measures to maintain a well-functioning fuel system and ensure reliable performance on the road.

Fuel System Components

Fuel Tank

The fuel tank is an essential component of the truck’s fuel system, responsible for storing and supplying fuel to the engine. It is typically made from high-grade materials like steel, aluminum alloy, or sometimes even reinforced plastic.

These materials are chosen for their durability and resistance to corrosion and damage caused by external factors such as debris on the road or extreme weather conditions. Fuel tanks come in various capacities and are designed to accommodate different truck sizes and operational requirements.

Smaller trucks may have tanks with capacities ranging from 20 to 50 gallons, while larger heavy-duty trucks can have tanks that hold up to several hundred gallons of fuel. The location of the tank also varies depending on the truck’s design, but it is commonly found underneath the chassis or mounted on either side of the vehicle.

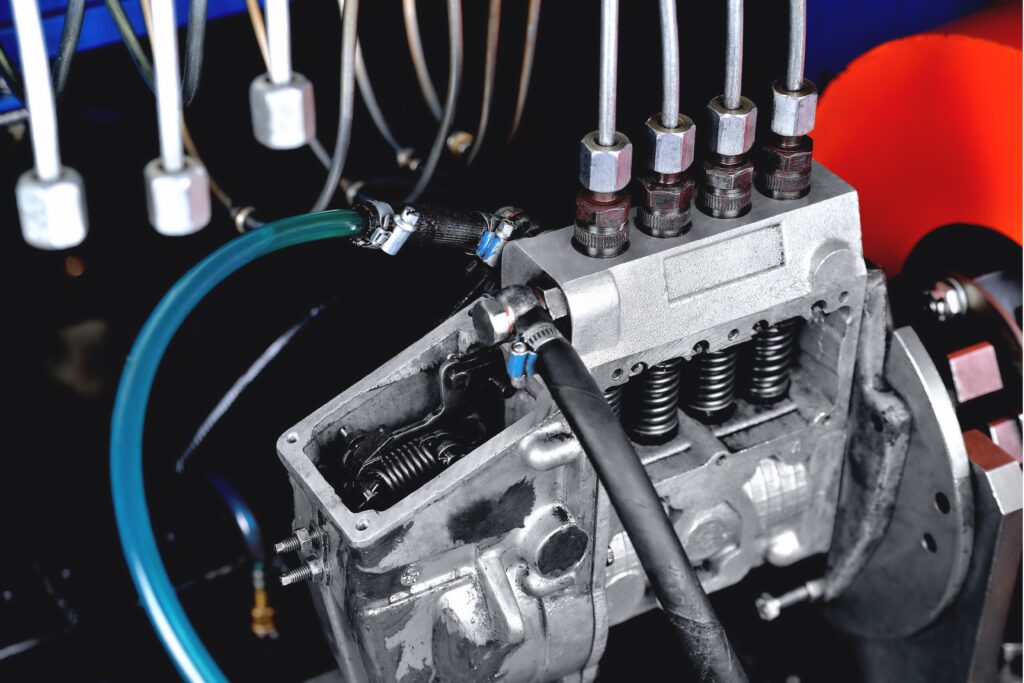

Fuel Pump

The fuel pump plays a vital role in ensuring a steady flow of fuel from the tank to the engine. There are two main types of fuel pumps used in trucks: mechanical pumps and electric pumps.

Mechanical pumps are typically driven by an eccentric lobe on the engine’s camshaft, which creates a pulsating motion that draws fuel from the tank into the pump through a suction pipe. Once inside, it pressurizes and pushes the fuel towards the carburetor or injectors depending on how old or modernized your truck’s system is.

On the other hand, electric pumps utilize an electric motor that generates continuous pressure to move fuel through the system. Electric pumps provide more consistent pressure compared to mechanical ones and are commonly found in newer trucks with electronic fuel injection systems.

Regardless of their type, both mechanical and electric pumps play a crucial role in maintaining proper fuel delivery by ensuring adequate pressure within the system. They also regulate flow rates according to engine demands while compensating for variations in altitude or other environmental factors.

Fuel Filters

Fuel filters are an integral part of the fuel system, responsible for removing impurities and contaminants from the fuel before it reaches the engine. They play a crucial role in safeguarding the engine’s performance and preventing damage or clogging of vital components. The primary purpose of fuel filters is to trap particles such as dirt, rust, or debris that may be present in the fuel tank or that might have entered during refueling.

By preventing these contaminants from reaching critical engine parts like injectors or carburetors, fuel filters help ensure smooth operation and prevent potential damage. There are different types of fuel filters available for trucks, including inline filters and spin-on filters.

Inline filters are typically placed between the fuel tank and the pump or between the pump and injectors/carburetors. Spin-on filters, as the name suggests, can be easily replaced by unscrewing them from a filter head and replacing them with a new one.

The choice of filter type depends on various factors such as compatibility with specific truck models, desired filtration efficiency, ease of maintenance/replacement, and manufacturer recommendations. Regular inspection and replacement of fuel filters are essential to maintain optimal performance and protect other components within the fuel system.

Fuel Injectors

Fuel injectors have a critical role in delivering precisely measured amounts of pressurized fuel directly into each engine cylinder. The injector’s design promotes efficient combustion by atomizing liquid fuel into a fine spray mist that mixes uniformly with incoming air in modern engines.

While performing this crucial task, injectors can encounter various issues that affect their performance. One common problem is carbon buildup on injector nozzles due to impurities in low-quality fuels or incomplete combustion processes.

Carbon deposits can restrict proper fuel flow or disrupt spray patterns leading to poor engine performance. Faulty seals around injector nozzles can also cause issues such as leaks or inconsistent fuel delivery, which can result in engine misfires or reduced power output.

Regular maintenance and inspection of injectors are essential to detect these issues early on. Diagnostic tools such as fuel pressure gauges or specialized equipment can help identify problems and determine whether cleaning, repair, or replacement is necessary.

The fuel system components discussed above form the foundational elements of a truck’s fuel system. Understanding their construction, functions, and potential issues will enable truck owners and operators to take proactive measures to maintain the efficiency and reliability of their vehicles while ensuring optimal performance on the road.

Common Issues with Truck Fuel Systems

Fuel Contamination

Fuel Contamination is a significant concern in truck fuel systems, as it can lead to severe engine performance issues and potentially shorten the engine’s lifespan. There are various types of contaminants that can infiltrate the fuel system, including dirt particles, water, and even microbial growth.

Dirt particles can find their way into the fuel through improper storage or handling practices, while water can enter the system due to condensation or leakage. When these contaminants enter the fuel system, they can cause a range of problems.

Dirt particles can clog filters and injectors, hindering proper fuel flow and reducing engine efficiency. Water in the fuel leads to corrosion of vital components such as pumps and injectors.

Moreover, microbial growth such as algae or bacteria colonies thrive in moist environments inside the tank and feed on hydrocarbons present in diesel fuel. This growth not only obstructs filters but also produces acidic byproducts that corrode metal surfaces.

To mitigate these issues caused by fuel contamination, it is crucial for truck owners and operators to employ preventive measures. Regularly inspecting storage tanks for leaks, employing proper filtration systems at refueling stations, and using additives that prevent microbial growth are effective strategies for reducing contamination risk.

Fuel Pump Failures

Fuel pump failures are another common issue faced by truck owners. These failures generally occur due to two main factors: wear and tear over time or electrical issues within the pump itself. With constant use, mechanical parts within a fuel pump experience gradual degradation.

The constant rotation of gears and vanes causes frictional wear that eventually leads to decreased pumping efficiency or complete failure. Electrical issues commonly arise from insulation breakdown or faulty connections within the pump assembly itself.

These problems may result in intermittent power supply disruptions causing irregular fuel flow. Identifying symptoms of potential fuel pump failure is critical for prompt troubleshooting and repair.

Some common signs include irregular engine idling, hesitation during acceleration, decreased fuel efficiency, and even difficulty starting the engine. When these symptoms are observed, it is prudent to consult a qualified mechanic who can use diagnostic tools to measure fuel pressure and assess the performance of the fuel pump.

Troubleshooting techniques often involve checking electrical connections, inspecting for physical damage or leaks in the pump assembly, and measuring voltage readings within the system. In cases where replacement is necessary, it is essential to select a high-quality pump that meets the manufacturer’s specifications to ensure optimal performance and longevity.

Solutions to Common Issues

Proper Maintenance Practices

Regular inspections for signs of contamination or wear are crucial for maintaining a healthy fuel system in trucks. Truck owners and operators should develop a routine inspection schedule to check for any visible signs of fuel contamination, such as the presence of dirt, water, or microbial growth. Regularly inspecting the fuel tank, filters, pumps, and injectors can help detect early warning signs of potential issues before they escalate into major problems.

By identifying problems at an early stage, maintenance can be performed promptly, preventing further damage to the system. Additionally, timely replacement of filters, pumps, and injectors is vital to ensure efficient fuel delivery and overall system performance.

Filters are designed to trap contaminants and prevent them from reaching sensitive components in the fuel system. Over time, these filters can become clogged and lose their effectiveness.

It is essential to replace them according to the manufacturer’s recommendations or earlier if excessive contamination is observed. Similarly, worn-out or malfunctioning pumps and injectors should be replaced promptly to avoid disruptions in fuel flow or inadequate combustion.

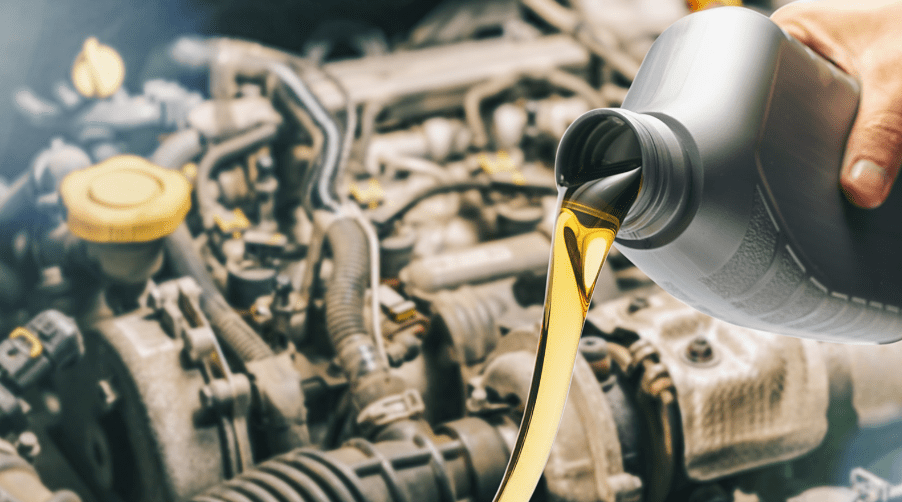

Use High-Quality Fuels

One cannot emphasize enough the importance of using clean fuels from reputable sources when it comes to maintaining a reliable fuel system in trucks. High-quality fuels with low levels of impurities minimize the risk of contamination-related issues that can impair engine performance and longevity. Reputable fuel suppliers adhere to stringent quality control measures during production and distribution processes that reduce the likelihood of contaminants entering your truck’s fuel system.

Choosing premium fuels that meet industry standards provides added assurance of optimal performance. Furthermore, consider additives that offer enhanced protection against certain contaminants or improve overall engine cleanliness when deciding on which fuels to use.

These additives can help prevent carbon deposits and keep injectors clean, promoting efficient combustion and reducing the risk of clogged components. By taking these measures, truck owners and operators can maintain the integrity of their fuel systems, minimize the occurrence of common issues, and maximize the performance and longevity of their vehicles.

Conclusion

A well-maintained fuel system is vital for proper truck operation. Regular inspections to identify signs of contamination or wear, along with timely replacements of filters, pumps, and injectors, are essential practices that help prevent common issues in fuel systems. Additionally, using high-quality fuels sourced from reputable suppliers ensures optimal performance by minimizing contamination risks.

By implementing these solutions diligently, truck owners can experience improved reliability in their vehicles’ fuel systems. Routine maintenance not only contributes to smooth operations but also helps avoid costly repairs down the line.

Remember to consult your vehicle manufacturer’s recommendations and work closely with trusted professionals to address any concerns promptly. With a commitment to effective maintenance practices and conscientious fuel choices, truck owners can enjoy peace of mind knowing their vehicles are equipped with reliable fuel systems that optimize performance while minimizing problems on long journeys or demanding work conditions.